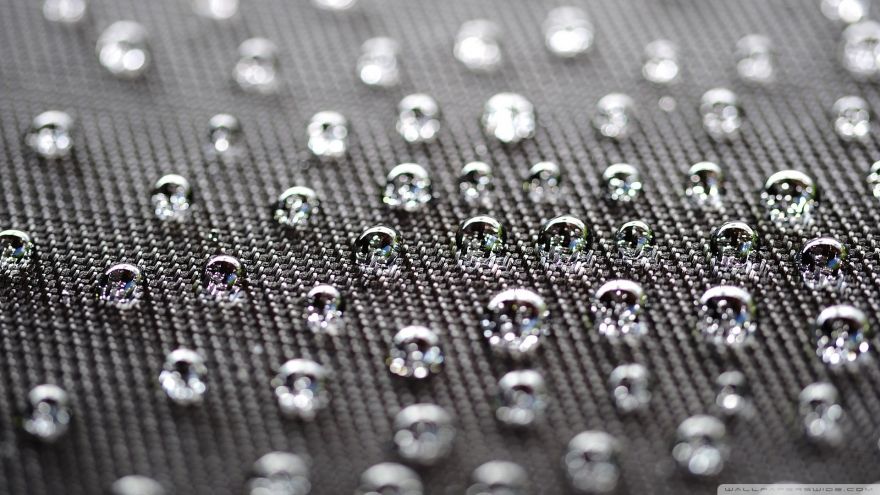

Water demineralization

Demineralization is the process of removing all the minerals that can be found in natural water in order to gain water of high purity. Such water, characterized by low electrical conductivity, is commonly used in many sectors of the economy such as: electronics industry, energy industry, pharmaceutical industry, cosmetic industry or food industry. The main processes of water demineralization include reverse osmosis (RO), ion exchange and electrodeionization (EDI).

REVERSE OSMOSIS – INDUSTRIAL RO SYSTEMS

Reverse osmosis systems are used for the production of demineralized water. They remove up to 90% of organic compounds and keep 98-99% of salts dissolved in water.

The advantages of RO systems:

- no need for the usage of chemical substances,

- no need for wastewater neutralization,

- easy service,

- a wide variety of equipment of efficiency adjusted to the customer’s needs.

The efficiency of particular systems depends on operating pressure, water temperature and the content of salts dissolved in natural water. Reverse osmosis systems need water pretreatment – sediment water filtration, water softening, iron and manganese removal.

RO technologies are widely used in car washes, heating plants, hospitals, laboratories, pharmaceutical and cosmetic industries.

ION EXCHANGE

The process of gaining demineralized water through the ion exchange technology. The system consists of two columns one of which is filled with a strong acid cation unit that works in the hydrogen cycle and the other one filled with a strong base anion unit that works in the hydroxide cycle.

As the ion exchange capacity nears exhaustion, the cation unit should be regenerated with a 6% hydrochloric acid solution (HCl) and the anion unit with a 3% sodium hydroxide solution (NaOH).

The system requires containers for storage and distribution of regenerants of proper strength of 33% HCl and 42% NaOH.

Since the slops are strongly acidic (pH 1-2) after the cation regeneration, and strongly alkaline (pH 11-12) after the anion regeneration, the proper wastewater treatment is needed to neutralize the slops.

ELECTRODEIONIZATION ( EDI )

The process which uses ion exchange and membrane techniques. The final product of this process is demineralized water of constant and high quality. The process of electrodeionization is marked by low power consumption without using chemical substances. EDI modules may work constantly and provide minimal water quality fluctuation.